Features:

1. Applicable for drilling holes, milling grooves, processing circular holes and special-shaped holes, and plane engraving of aluminum alloy profiles.

2. Controlled by the CNC system, and using import 9KW main spindle from Italy, smooth operation and high precision.

3. Adopting 18000 RPM electric main spindle and milling edge do not have the burr.

4. X axis adopts high-precision helical gear and rack, Y and Z axis adopts high-precision ball screw transmission.

5. The machine can read standard G-code and third-party programming software is workable to match it.

6. Worktable can turn -90°,~0° ~+90°, which can realize three-sides processing by clamping one time.

7. It can process deep and special-shaped holes through the worktable.

8. The machine equip the 6 tools magazine, which can realine fast tool-auto change function.

Parameters:

|

Model |

LJX-CNC-3000 |

|

Work stroke |

|

|

X-Axis Stroke |

3000mm |

|

Y-Axis Stroke |

300mm |

|

Z-Axis Stroke |

200mm |

|

Precision |

|

|

X-axis position precision |

±0.05mm |

|

Y/Z axis position precision |

±0.05mm |

|

Power |

|

|

Machine Power |

12 KW |

|

Spindle Power |

9 KW |

|

Working Pressure |

0.5-0.8Mpa |

|

Work Speed |

|

|

X Working Speed |

0-60m/min |

|

Y Working Speed |

0-30m/min |

|

Z Working Speed |

0-30m/min |

|

Spindle Speed |

0-24000rpm/min |

|

Tools Specification |

|

|

Max.Tool Length |

130mm |

|

Spindle Taper |

IS030 |

|

Tools Magazine |

6 Tools |

|

Machine Specification |

|

|

Machine Voltage |

380V 50HZ 3PH |

|

Dimension |

5550x1800x2100mm |

|

Weight |

1600KGS |

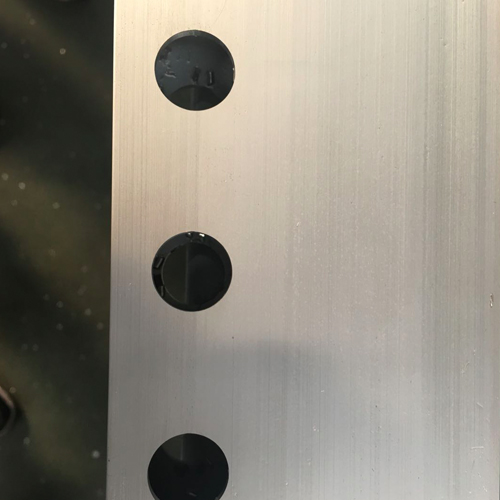

Detailed Pictures